A wide variety of industrial applications involve laser beams. However, these application areas require modified laser beams with uniform distribution patterns rather than natural ones. Most laser beams naturally exhibit light radiation through a Gaussian distribution pattern. In this beam distribution pattern, the irradiance level decreases slowly, with the highest irradiance value at the center. As the edges expand infinitely in this intensity distribution pattern, it causes a significant energy loss. A laser beam must display a uniform intensity distribution pattern to avoid the loss of light energy. Laser beam shaping modifies an input beam into a unique output beam so that it displays a uniform intensity pattern.

Different Laser Beam Transformations

Laser beam transformations involve special optical components called diffractive optical elements or DOEs. These optical elements apply the diffractive principle to transform a laser beam into a well-structured output beam. There are three major types of laser beam transformations that use diffractive optical elements to modify the input beams, such as laser beam shaping, laser beam splitting, and focal beam shaping.

Laser Beam Shaping

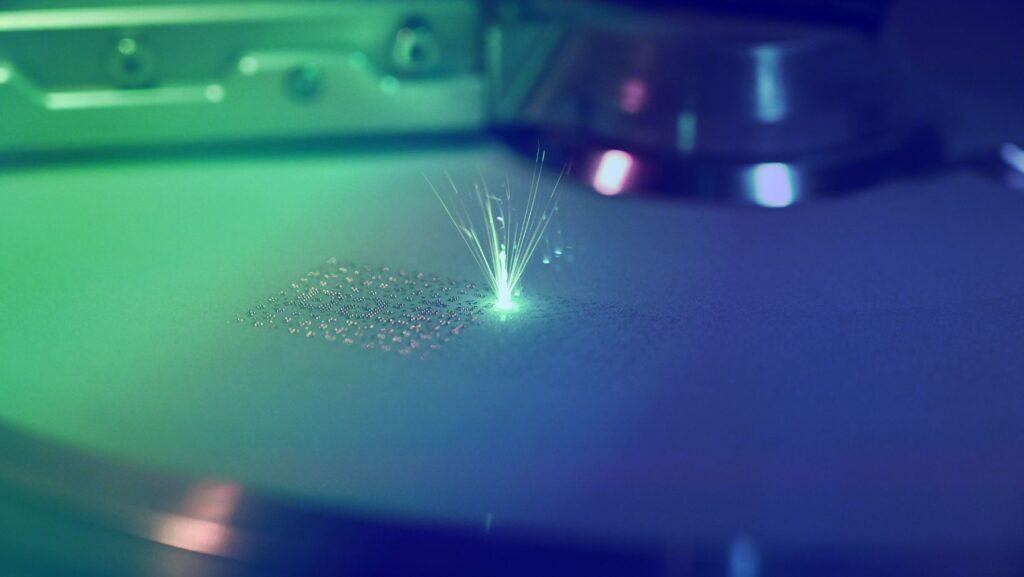

Diffractive optical elements are essential for spatial beam shaping which involves transforming a Gaussian distribution pattern into a Flat Top intensity distribution pattern.

These optical elements can generate uniform spots with sharp borders and different geometrical shapes.

Laser Beam Splitting

Laser beam splitting involves splitting an input laser beam into various output beams. Apart from the propagation angle and power, the output beams’ other characteristics remain the same as the input laser beam. Beam splitters have significant quantum applications for distributing laser power and monitoring laser systems.

Focal Beam Shaping

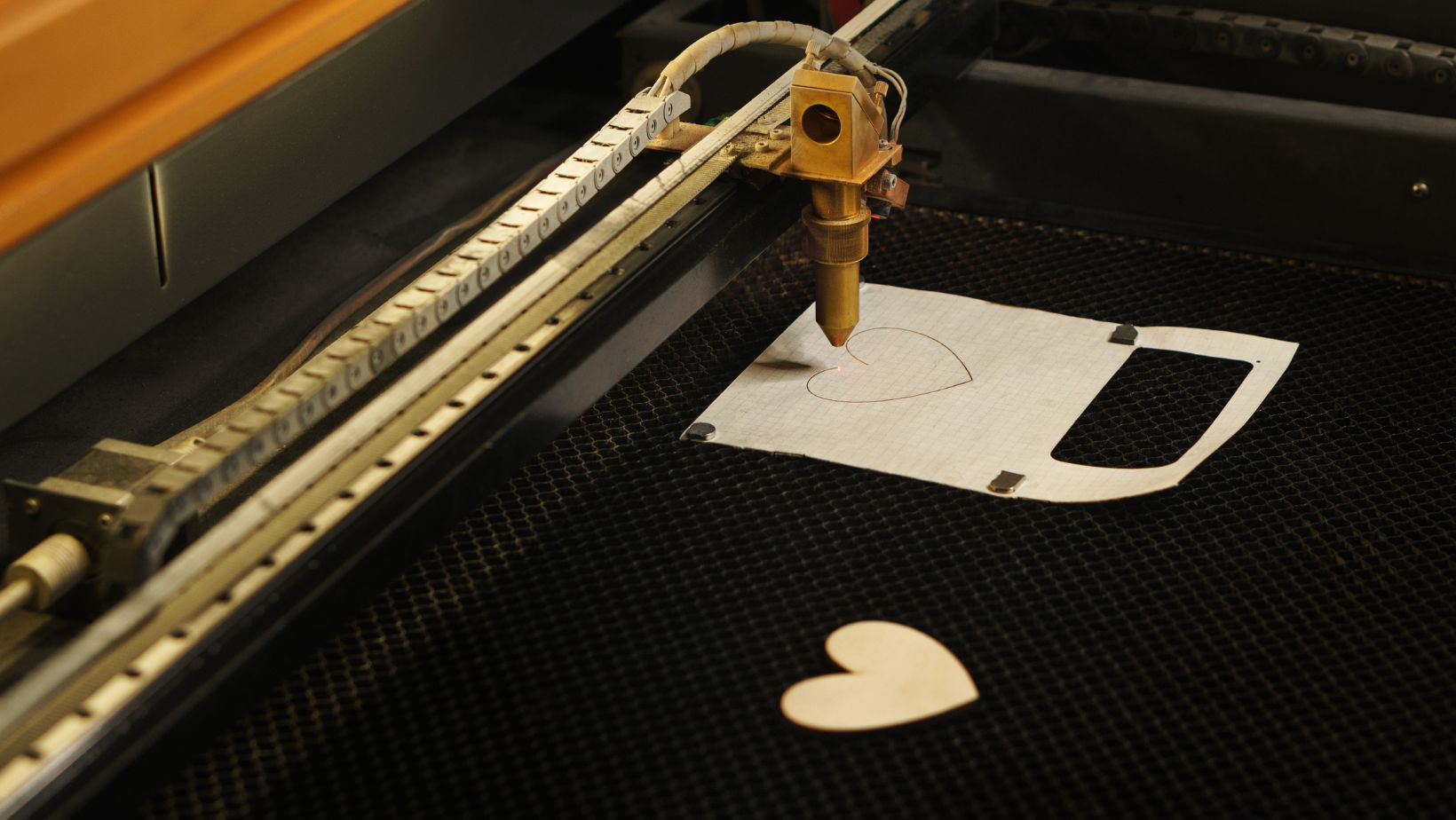

Diffractive optical elements shape input laser beams along their propagation axes in focal beam shaping. These optical elements stretch the input beam to elongate its beam waist.

DOEs in Laser Beam Shaping

Most naturally occurring laser beams display a non-uniform Gaussian intensity distribution pattern.

The absence of sharp borders in this beam pattern causes a substantial energy loss. Industrial laser applications can not afford this energy loss. These applications rely on laser beam shaping to shape a laser beam and generate a unique beam profile with uniform intensity distribution.

Diffractive optical elements act as laser beam shapers in beam shaping. A Flat Top beam shaper removes the non-uniformity in an input beam pattern and transforms it into a well-defined, uniform intensity pattern with a constant irradiance level. Flat-top beam shapers are efficient for eliminating fat cells beneath the lower skin. In aerial skin treatments such as tattoo removal, diffractive optical elements are useful. These optical elements can generate beam patterns with various geometrical shapes. The two common beam shapes that laser beam shaping produces are rectangular and hexagonal. Diffractive beam splitters also have several important aesthetic medicine applications.